The Takeaway

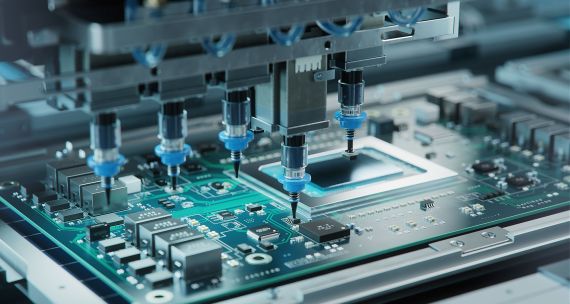

As India jockeys to become a global “chip-making superpower,” foreign investment in the country’s semiconductor industry becomes crucial. As tech giants like Foxconn and Micron weave their way into the country’s semiconductor fabric through recent significant investments, the government must improve the business environment, create employment opportunities, and strengthen internal infrastructure.

In Brief

Global leaders commended India’s technologically forward presidency during the G20 Summit in New Delhi in September. Mark Rutte, the prime minister of the Netherlands, announced that his government is exploring the possibility of collaborating with the Indian and Karnataka governments to expand the semiconductor industry in Bengaluru, Karnataka’s capital city. Multiple foreign investments have poured in to strengthen India’s semiconductor sectoral growth. Micron invested C$1.1 billion (68.1 billion Indian rupees), while Foxconn announced a C$270-million investment (16.7 billion Indian rupees) in the country. Bengaluru also secured a US$400-million (33 billion Indian rupees) investment from U.S.-based Advanced Micro Devices (AMD) to set up a research facility on artificial intelligence and machine learning.

Implications

- Favourable government policies to sustain FDI

In 2019, India’s Ministry of Electronics and Information Technology introduced the National Policy on Electronics to facilitate the growth and development of the domestic semiconductor industry, introducing several incentives to support national enterprises and attract foreign investors. The Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors is designed to foster the growth of a national supply chain, while the Product Design Linked Incentive will cover up to 50 per cent of eligible expenses with a maximum limit of C$2.4 million (150 million Indian rupees). The Chips to Start Up scheme will train 85,000 people from startups, R&D facilities, micro, small, and medium enterprises, and academic institutions over five years in different chip technologies like VLSI and Embedded System Design. The government has also given the green light to modernize and transform a Mohali-based semiconductor lab into a brownfield chip manufacturing unit.

- India’s motivation to grow semiconductor capabilities

As the West reduces its reliance on China for manufacturing, India becomes the preferable alternative, encouraging firms to diversify supply chains by tapping into its expanding semiconductor sector that offers access to a vast domestic market, affordable manufacturing, and export potential. With a digital-first approach, India has put a strong emphasis on making its semiconductor industry domestically self-reliant. In tandem with the “Make in India” initiative launched in 2014 by the Indian government to foster the development, production, and assembly of products within the country, the ambitious India Semiconductor Mission (ISM) also hopes to create a similar thriving semiconductor and display industry to support its ascent into a worldwide centre for electronics production and innovation, surpassing China’s global influence in this sector. But India’s success depends on continual government efforts to improve the business environment and foster interstate collaborations.

What’s Next

- Developing a skilled workforce

India aims to expand its semiconductor workforce to 1.2 million by 2032. To achieve this, an additional 275,000 skilled professionals are required in chip design, 25,000 in semiconductor fabrication, and 29,000 in assembly, testing, marking, and packaging (ATMP) operations. To address this need, the Electronics Sector Skills Council of India and the Electronic Industries Association of India have jointly launched SEMI University, an online platform offering 360 courses covering manufacturing, chip design, artificial intelligence, and workplace safety. U.S.-based LAM Research will introduce virtual nanofabrication through its simulation platform Semiverse, training 60,000 engineers in the next decade. Furthermore, Purdue University, jointly with ISM, will offer certificate courses in circuit and system design and advanced packaging and manufacturing beginning in 2024.

- Building strong internal infrastructure

As India witnesses rapid technological advancement, it will also need strong policies, research and development, and infrastructure to enable its national semiconductor enterprises. Deloitte predicts the Indian semiconductor market to reach US$55 billion by 2026. The Indian government, therefore, will need to ensure that there is strong and reliable internal infrastructure to meet this demand. The government needs to focus on back-end manufacturing, or ATMP, a central component of the supply chain. Prioritizing investing in power, hydro, and transportation could establish India as a semiconductor hub, while incentives for a local vendor base and supply chain, along with tariffs, regulations, and subsidies, can attract investors and support domestic stakeholders, further strengthening ISM.

- Impact of recent Canada-India spat

The trajectory of India's semiconductor industry could face challenges if other nations adopt protectionist policies to limit trade. Consequently, despite India being seen as replacing China in terms of economic prospects, recent statements from Canadian Prime Minister Justin Trudeau linking the Indian government to the assassination of a pro-Khalistan leader on Canadian soil could chill that optimism. Time will tell, but initial reactions seem to indicate that major countries will avoid getting involved in what has been described as “private discussions.”

• Produced by CAST’s South Asia team: Prerana Das (Analyst); Suyesha Dutta (Analyst); and Deeplina Banerjee (Analyst).